Cost-effective membrane intensified processes for CO2 capture and conversion to shipping fuels

One of the primary objectives of HTF is the advancement of membrane intensified processes to establish CO2 as a valuable resource and a compelling business opportunity, particularly in the cost-effective production of shipping fuels, based on recent advances in nano-enabled membranes and catalysts. This concept contrasts with considering CO2 as a waste, burdened by expenses related to its disposal. CO2 will be a feedstock of negative cost for conversion to fuels and chemicals. In comparison with the concept of carbon sequestration and storage (CSS), the main disadvantages of CCS are the high cost of CO2 transport to distant sequestration sites, the safety of the sequestration sites, and the impact on the environment.

- “Next-generation” CO2 capture membranes aim to reduce the CO2 capture cost by 45%. The main objective is to reduce the compression costs of large biogas (and flue gas) streams by deploying high CO2 permeance membranes. To this end, HTF, in close cooperation with Southeastern Research, Innovation and Education RI, has developed a novel Layer-by-Layer (LBL) deposition of functionalized GOs to fabricate high CO2 permeance membranes.a

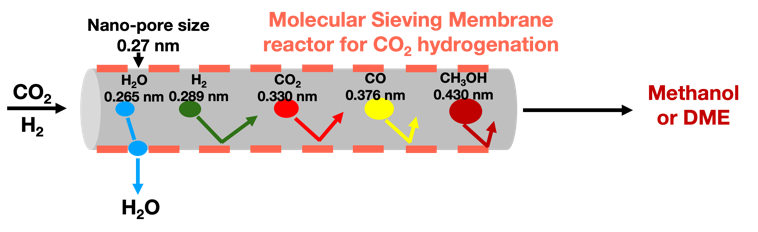

- Next-generation” Molecular Sieving (MS) membranes for the cost-effective conversion of biogas to shipping fuels.

The objective is to reduce the costs of CO2 conversion to oxygenates, methanol, and, in the second stage, DME, a potential diesel substitute.

HTF has achieved H2/CO2 selectivities greater than 100. The dehydrogenation MS membranes developed present the advantage of lower cost and higher durability compared to conventional Pd alloy membranes and effectively address the major challenge of hydrogenation technologies, which is the high hydrogen cost. This can lead to a 35% reduction in the cost of H2, which is a major drawback of the CO2 hydrogenation processes.

In addition, Molecular Sieving membranes with the H2O/H2 selectivities greater than 18 have been developed with water permeance greater than 6000 GPU. These membranes are expected to outperform the zeolitic and carbon dehydration membranes for the production of methanol and DME.